What is Grounding? How is it Measured?

Grounding, also referred to as earthing, is a crucial safety measure in electrical systems that protects both people and equipment...

Devamını Oku

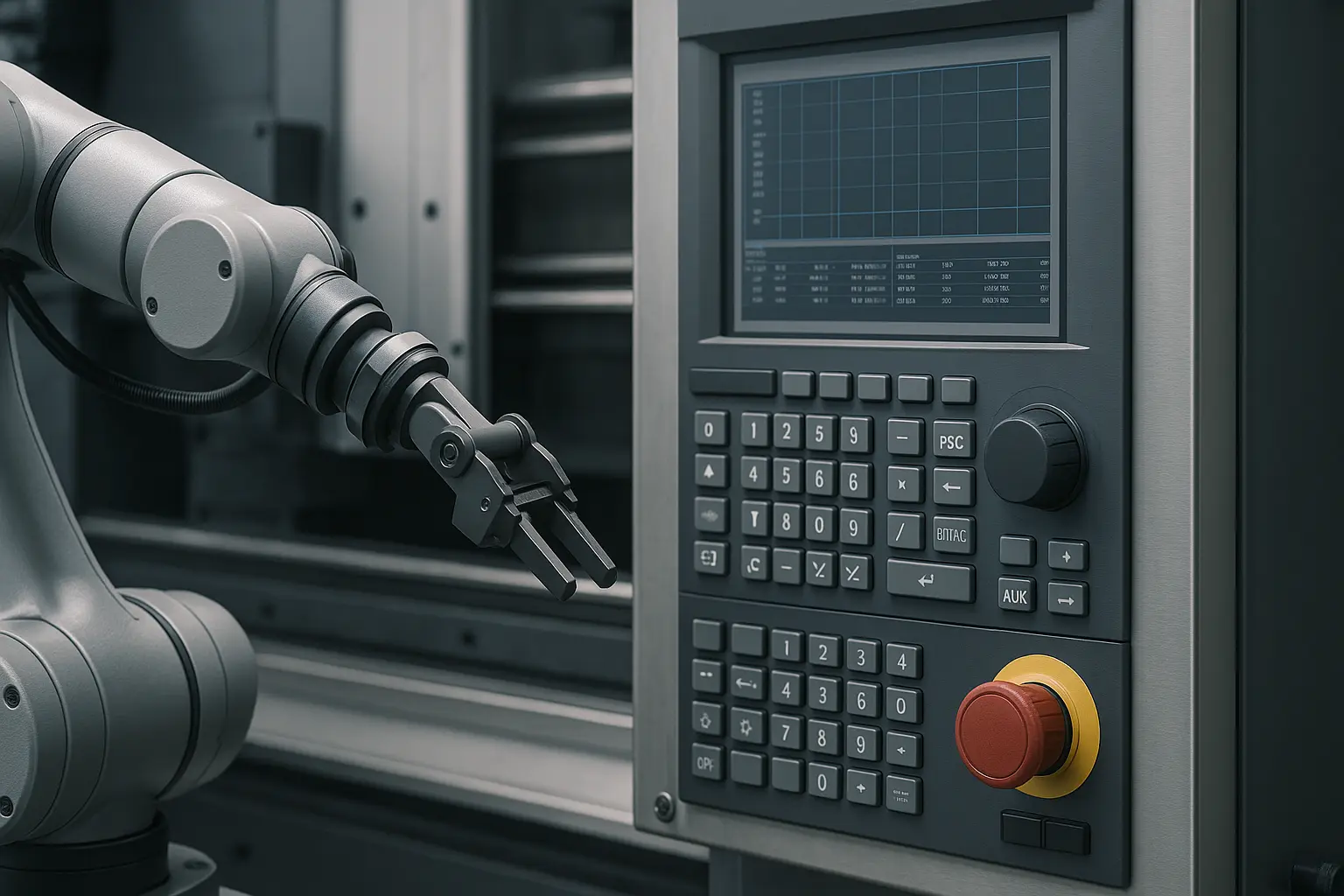

Machine automation systems are essential technologies used to improve production efficiency, reduce human error, and enhance product quality in industrial operations. These systems allow machines to operate independently with minimal human intervention, resulting in faster, safer, and more sustainable production processes. With the growing importance of Industry 4.0, machine automation has become a cornerstone for smart manufacturing across many sectors.

Adatech stands out in this field by offering innovative and customized solutions in machine automation systems. From medium and low voltage electrical infrastructure to control systems and mechanical installations, Adatech provides end-to-end services tailored to industrial needs. Among machine automation companies in Istanbul, Adatech is known for its engineering expertise, technical precision, and commitment to quality.

In modern industrial ecosystems, automation is no longer optional—it’s a strategic necessity. By integrating advanced control technologies and seamless communication between hardware and software, Adatech supports businesses in their digital transformation journeys. As a leader among machine automation companies, Adatech’s solutions enable enhanced productivity, energy efficiency, and operational excellence, solidifying its place in the Istanbul machine automation market.

Machine automation refers to the use of control systems, such as computers and programmable logic controllers (PLCs), to operate machines and processes with minimal or no human intervention. These systems manage repetitive tasks with consistency, improving efficiency and reducing operational errors. By automating workflows, businesses can increase productivity and maintain consistent quality across production lines. In today’s digital-driven manufacturing environments, understanding what is machine automation is crucial for companies seeking scalability and competitiveness.

Machine automation systems play a vital role in smart factories by integrating sensors, controllers, and actuators to manage operations in real time. Companies like Adatech specialize in engineering custom solutions that align with the unique needs of each industry. As one of the top machine automation companies in Istanbul, Adatech enables businesses to transition into more efficient and data-driven operations.

Machine automation systems are integrated solutions that combine hardware and software components to control industrial machines and processes automatically. These systems typically consist of sensors, actuators, programmable controllers, human-machine interfaces (HMIs), and software platforms. Their main goal is to boost efficiency, reduce operational costs, and improve safety and quality in production environments. A well-designed system ensures consistent performance with minimal downtime and human error.

As one of the leading machine automation companies, Adatech develops custom automation infrastructures tailored to specific industrial needs. Their solutions range from single-machine automation to complex, fully connected smart factory systems. In the highly competitive Istanbul machine automation market, Adatech provides scalable and future-ready systems that empower manufacturers to embrace digital transformation and stay ahead of industry trends.

In machine automation systems, power and control components are the foundation of reliable operations. These include motors, contactors, relays, circuit breakers, and power supplies that ensure stable energy flow and precise control. Adatech integrates high-quality components into its systems, helping businesses achieve greater efficiency and performance in their machine automation infrastructure.

Programmable controllers (PLCs) and drives are essential elements in machine automation systems, providing precise control over industrial processes. PLCs manage workflows and decision-making logic, while drives regulate motor speed, torque, and energy efficiency. Adatech delivers high-performance PLC and drive solutions, ensuring seamless integration and maximum reliability in modern machine automation projects.

Human-Machine Interfaces (HMI) enable operators to monitor and control industrial systems through intuitive, visual dashboards. These interfaces simplify complex processes by displaying real-time data, alarms, and performance metrics. Adatech integrates advanced HMIs into its machine automation systems, providing user-friendly solutions that improve efficiency, safety, and decision-making across production environments.

Machine automation operates through a coordinated process that involves collecting input data, analyzing it, and executing corresponding actions. Sensors detect variables such as temperature, pressure, or speed and send the information to controllers. These controllers process the data and determine the necessary commands, which are then carried out by actuators and motors. The result is a smooth and reliable automated workflow with minimal human involvement.

In advanced machine automation systems, the entire process is monitored in real time, allowing businesses to optimize production efficiency and detect issues immediately. Adatech, a trusted name among machine automation companies in Istanbul, designs automation infrastructures that ensure seamless operation, cost reduction, and enhanced performance in diverse industrial applications.

Sensors are the eyes and ears of machine automation systems, capturing real-time data from the production environment. They measure variables like pressure, temperature, speed, and position, ensuring accuracy throughout the process. Adatech leverages advanced sensors to enhance reliability and efficiency, making machine automation smarter and more responsive to industrial needs.

Control mechanisms are the decision-making core of machine automation systems, interpreting sensor data and executing commands through actuators and motors. Programmable logic controllers (PLCs) and microcontrollers ensure tasks are carried out precisely and consistently. Adatech integrates robust control solutions, enabling businesses to maximize productivity and reliability in their machine automation infrastructure.

In machine automation, automatic monitoring and feedback processes ensure continuous performance and reliability. Data collected from sensors is analyzed instantly, and corrective actions are applied when deviations occur. Adatech designs advanced feedback loops within its machine automation systems, helping industries maintain efficiency, reduce downtime, and achieve consistent quality in their operations.

Machine automation is widely used across various industries to increase efficiency, reduce costs, and maintain consistent quality standards. In the automotive sector, automation ensures precision in assembly lines; in food and beverage, it enhances packaging and quality control; and in pharmaceuticals, it guarantees compliance and accuracy in production. These examples show how machine automation systems have become indispensable for modern industries.

As one of the leading machine automation companies, Adatech delivers tailored solutions for diverse fields such as energy, textiles, chemicals, and logistics. By leveraging advanced control technologies and smart data integration, Adatech helps clients achieve long-term sustainability. In the highly competitive Istanbul machine automation market, the company’s expertise supports businesses in adopting innovative practices for digital transformation.

Grounding, also referred to as earthing, is a crucial safety measure in electrical systems that protects both people and equipment...

Devamını Oku

PRMS (Pressure Reduction and Metering Stations) are critical components of natural gas infrastructure, ensuring the safe and efficient delivery of...

Devamını Oku

Transformer maintenance refers to the systematic inspection, testing, cleaning, and repair of transformers to ensure their optimal performance and prevent...

Devamını OkuPROTECTION OF PERSONAL DATA

WEBSITE COOKIE POLICY

Your personal data; It is one of the leading principles of our Organization to protect the privacy of visitors to the website (www.adatech.com.tr) operated by ADATECH as the data controller. This Cookie Usage Policy (“Policy”) explains to all our website visitors and users which types of cookies are used and under what conditions.

Cookies are small text files stored on your device or network server by websites you visit on your computer or mobile device.

They are generally used to provide you with a personalized experience during your use of the website you visit, to improve the services offered and to improve your experience, and may contribute to ease of use while browsing a website. If you do not prefer the use of Cookies, you can delete or block Cookies in your browser settings. However, we would like to remind you that this may affect your use of our website. Unless you change your cookie settings in your browser, we will assume that you accept the use of cookies on this website.

1. WHAT KIND OF DATA IS PROCESSED IN COOKIES?

Cookies on websites, depending on their type, collect data about your browsing and usage preferences on the device you visit the site. This data includes information about the pages you access, the services and products you review, your preferred language option and other preferences.

2. WHAT is a solution and what are its intended uses?

Cookies are small text files that are stored on your device or network server through browsers by websites you visit. These small text files, which contain your preferred language and other settings on the site, help us remember your preferences the next time you visit the site and make improvements to our services to improve your experience on the site. Thus, you can have a better and personalized usage experience on your next visit.

The main purposes of using cookies on our Website are listed below:

3.TYPES OF COOKIES USED ON OUR WEBSITE

3.1. Oturum Çerezleri

Session cookies ensure that the website functions properly during your visit. They are used for purposes such as ensuring the security and continuity of our sites and you during your visit. Session cookies are temporary cookies, they are deleted when you close your browser and come to our site again, they are not permanent.

3.2. Persistent Cookies

These types of cookies are used to remember your preferences and are stored on your device via browsers. Persistent cookies remain stored even after you close your browser or restart your computer from which you visited our site. These cookies are kept in subfolders of your browser until they are deleted through your browser’s settings.

Some types of persistent cookies may be used to provide you with special suggestions, taking into account issues such as your purpose of using the Website.

Thanks to persistent cookies, if you visit our Website again with the same device, it is checked whether there is a cookie created by our Website on your device and if there is, it is understood that you have visited the site before and the content to be transmitted to you is determined accordingly and thus a better service is provided to you.

3.3. Mandatory/Technical Cookies

These cookies are essential for the website you visit to function properly. The purpose of such cookies is to provide necessary services by enabling the website to function. For example, it allows you to access secure parts of the website, to use its features, to navigate on it.

3.4. Analytical Cookies

They collect information about the way the website is used, the frequency and number of visits, and show how visitors navigate to the site. The purpose of using such cookies is to increase performance by improving the way the site functions and to determine the general trend direction. They do not contain data that could enable the identification of visitors. For example, they show the number of error messages displayed or the most visited pages.

3.5. Functional/Functional Cookies

It saves the choices made by the visitor within the site and remembers them on the next visit. The purpose of such cookies is to provide ease of use to visitors. For example, it prevents the site user from re-entering the user password on each page they visit.

3.6. Targeting/Advertising Cookies

They enable the measurement of the effectiveness of advertisements served to visitors and the calculation of the number of times the advertisements are viewed. The purpose of such cookies is to serve ads customized to the interests of visitors.

Likewise, they enable the detection of visitors’ interests specific to their browsing and the presentation of appropriate content. For example, it prevents the advertisement shown to the visitor from being shown again in a short time.

4. HOW TO MANAGE COOKIE PREFERENCES?

To change your preferences regarding the use of cookies or to block or delete cookies, simply change your browser settings.

Many browsers give you the option to accept or reject cookies, accept only certain types of cookies, or be alerted by the browser when a website requests to store cookies on your device so that you can control cookies.

It is also possible to delete cookies previously saved in your browser.

If you disable or refuse cookies, you may need to set some preferences manually, some features and services on the website may not function properly as we will not be able to recognize and associate your account. You can change the settings of your browser by clicking on the relevant link from the table below.

5. ENFORCEMENT OF WEBSITE PRIVACY POLICY

Website Privacy Policy …./…./…./…. . is dated. In case all or certain articles of the Policy are renewed, the effective date of the Policy will be updated. The Privacy Policy is published on the website of the Authority (www.adatech.com.tr) and made available to the relevant persons upon the request of the personal data owners.

ADATECH

Address: Esenyalı Neighborhood Yanyol Street Varyap Plaza No:61-148 Pendik / Istanbul

Telephone: +90 (216 ) 514 80 69

E-mail: [email protected]

Web Address: www.adatech.com.tr