With advance data monitoring, AI-powered analytics, and flexible integrations, we are shaping not only today but also the future. While our advanced reporting tools help you manage every moment more efficiently, our technologies that bridge the digital and physical worlds make a real difference.

As Adatech, the distributor of Omnivex® SCADA and Proveris® OEE software, we bring this vision to life by making your processes more effective, reliable, and sustainable.

By embracing sustainability at every step, we guarantee uninterrupted operations and a secure infrastructure. By integrating technology into every corner of your business processes, we accelerate your digital transformation.

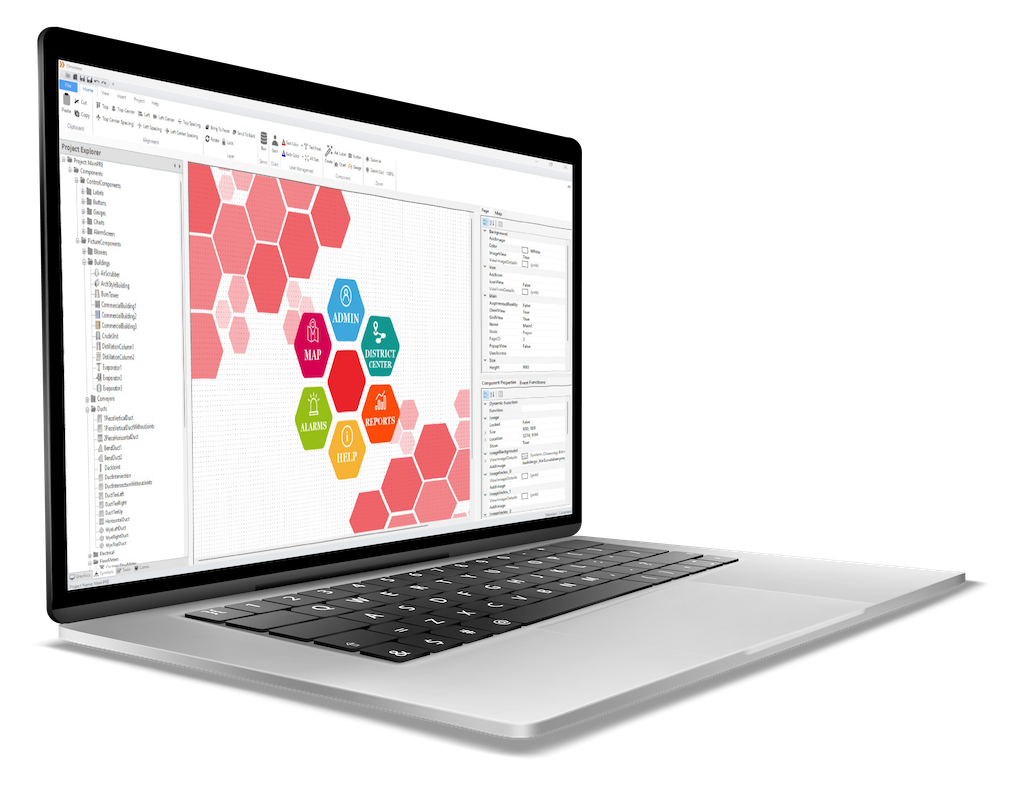

Omnivex® SCADA

It offers a holistic approach that enables you to manage all your processes with ease. With its user-oriented design and technological integrations, it organizes your workflows and transforms your data into meaningful insights. Designed with reliability and flexibility in mind, it adds value to your business processes.

SCADA Features Raising Standards

User-Friendly Interface

You can simplify the visualization and management of complex processes with drag-and-drop functionality, graphical indicators, and clear menu structures.

Communication Protocols

You can easily perform data integration via Modbus TCP/RTU, MQTT, OPC UA, and BACnet, and establish seamless communication with PLCs, sensors, and devices.

Real-Time Data Monitoring and Control

You can collect real-time data from field equipment, monitor live processes, and track all operations from a single center to enable quick interventions.

Advanced Reporting and Data Analysis

You can obtain real-time and historical data through automatic or customizable reports, and easily detect trends and anomalies using advanced analytics.

Alarm Management

You can receive automatic alarms with visual, audible, SMS, and email notifications for threshold breaches; advanced prioritization, classification, and logging help accelerate your response time.

Recipe Management

You can simplify the visualization and control of complex processes with drag-and-drop graphical indicators and clear menus.

Server Redundancy

You can prevent system downtime, minimize data loss, and ensure uninterrupted operations with automatic backup server takeover.

Integrated Web Server

With the Web Server, you can securely access the system anytime and anywhere via web browsers on mobile devices and tablets.

Proveris® OEE

Our OEE software offers a holistic approach to optimize production. By combining a user-friendly design with seamless integrations, it transforms raw data into actionable insights. It adds value to your business by helping identify bottlenecks, reduce waste, and increase efficiency.

Elevate Your Production Performance

Comprehensive OEE Indicators and Overview

You can view organization-wide OEE data at a glance on a single page. Instantly drill down to device-level indicators such as Availability, Performance, and Quality; quickly access fault logs and output counts to better understand and improve production.

Machine Definition and Customized Tracking

You can add unlimited machines and include all production lines in the OEE system. With dedicated pages that provide detailed tracking and analysis for each unit, you can effectively manage all your assets at any scale.

Advanced Reporting and Data Analysis

You can create automatic and customizable production reports. Export data in various formats such as PDF, Excel, or CSV, and transform raw data into clear insights through advanced analytics. This enables you to make faster and smarter decisions.

Instant Data Access with Augmented Reality (AR)

You can access live machine data on the shop floor using Augmented Reality (AR) technology. By scanning a machine’s QR code with your computer camera, you can view real-time measurements directly on the asset. This allows teams to make quicker decisions and respond instantly to potential issues.

Empower Your Decisions with Adatech Software Solutions:

Real-Time Data

You can monitor your processes at any time with real-time data. This way, you can make quick decisions and minimize production errors and losses.

Smart Reporting

With advanced reporting tools, you can turn raw data into meaningful insights. This way, you can measure your performance and confidently shape your strategic decisions.

Data Protocol

You can establish seamless communication between your devices through different protocols such as Modbus, MQTT, and OPC UA. This compatibility makes your systems more flexible and robust.

Operational Efficiency

With automation, you can reduce time losses and use your resources in the most efficient way. This allows you to achieve higher performance in your production processes.

Seamless Integration

You can easily integrate into your existing systems and work in harmony with different technologies. This structure makes your investments future-ready.