What is Automation? What Does It Do?

In the age of digital transformation, automation has become an essential component across industries. From manufacturing to healthcare, logistics to...

Devamını Oku

PRMS (Pressure Reduction and Metering Stations) are critical components of natural gas infrastructure, ensuring the safe and efficient delivery of gas from high-pressure transmission lines to end-users. These stations are responsible for reducing the gas pressure to acceptable levels for downstream systems while simultaneously measuring flow rates and other parameters to guarantee safe operations. PRMS systems play a key role in maintaining the stability and reliability of gas distribution networks in both industrial and residential settings.

Pressure reduction and metering stations are not merely passive flow control points—they are intelligent, automated systems that monitor and adjust gas parameters in real time. Thanks to their integration with modern SCADA and telemetry technologies, PRMS facilities allow remote monitoring and instant intervention, making them an essential part of today’s digital energy management infrastructure. The proper design, installation, and operation of PRMS systems help prevent energy losses, ensure safety, and optimize performance. With the expertise of engineering firms like Adatech, these systems continue to evolve into smarter and more sustainable solutions for the energy sector.

PRMS stands for Pressure Reduction and Metering Stations and plays a vital role in managing natural gas distribution. They ensure that gas pressure is safely reduced to suitable levels before it enters consumer networks. These systems accurately measure gas flow to guarantee effective energy usage. They are integral components of both industrial and residential gas supply infrastructures. Their design reinforces the safety, reliability, and efficiency of energy transmission.

In the energy sector, PRMS systems are recognized as strategic assets that drive operational safety. They support scalable, sustainable, and highly efficient energy distribution networks. Each station is integrated with advanced digital control technologies for precise performance monitoring. This technology not only tracks real-time metrics but also facilitates prompt maintenance interventions. Thus, the role of Pressure Reduction and Metering Stations remains indispensable for modern energy systems.

The core function of a PRMS system is to reduce the pressure of natural gas transmitted through pipelines, adjusting it to safe and usable levels for downstream distribution. This reduction ensures that gas can be safely delivered to various users—ranging from industrial facilities to residential networks—without posing risks to equipment or infrastructure. Additionally, PRMS systems perform precise metering, measuring gas flow rates and volumes, which is essential for billing, energy management, and regulatory compliance.

Beyond pressure control and flow measurement, PRMS systems offer protection and operational intelligence. These stations are equipped with safety valves, filters, and regulators to respond to abnormal conditions such as overpressure or high flow rates. Many PRMS installations also feature advanced sensors and data acquisition systems to monitor temperature, density, and gas composition. These capabilities help prevent leaks, reduce operational costs, and maintain system integrity. In this way, Pressure Reduction and Metering Stations function as both protective and analytical hubs within the broader gas infrastructure.

A PRMS station is a complex system composed of several key components that work together to ensure safe, reliable, and efficient gas distribution. Among the most critical pieces of equipment are pressure regulators, which reduce high-pressure gas to levels appropriate for end use. These regulators maintain a constant downstream pressure despite fluctuations in upstream flow. Another essential component is the flow meter, which measures the volume of gas passing through the station with high accuracy, supporting precise billing and consumption tracking.

Additional critical equipment includes gas filters, which remove contaminants like dust or oil that can damage pipelines and downstream devices. Safety valves and shut-off valves are also installed to protect the system in the event of sudden pressure surges or emergencies, automatically stopping the gas flow when necessary. Gas heaters are sometimes used to prevent the temperature drop associated with pressure reduction, which could lead to condensation or freezing. Modern PRMS stations also incorporate automation panels and SCADA systems for remote monitoring and control. Together, these components ensure that Pressure Reduction and Metering Stations operate smoothly, safely, and in compliance with industry standards.

The installation of a Pressure Reduction and Metering Station (PRMS) involves a detailed, multi-phase process that requires high engineering precision. It begins with a feasibility study to assess gas demand, site conditions, and compliance requirements. Based on these findings, the engineering design phase includes pressure and flow calculations, equipment selection, layout planning, and safety protocols. This stage ensures the system will meet both technical and regulatory standards. Once the design is finalized, necessary permits and approvals from regulatory bodies are secured before moving into implementation.

The construction phase starts with site preparation and civil works, followed by mechanical and electrical installations. Equipment such as regulators, meters, filters, and control panels are mounted, piped, and connected. Once assembly is complete, rigorous testing procedures—including pressure testing, leak checks, and functionality tests—are conducted to ensure safety and reliability. After successful testing, the station is commissioned, during which all system parameters are fine-tuned, and remote monitoring systems are activated. Operators are trained, and maintenance protocols are established. Firms like Adatech manage this entire process using international best practices, ensuring that the PRMS station is efficient, safe, and future-ready.

PRMS systems are vital wherever natural gas is distributed and consumed in significant volumes. Their primary usage areas include industrial zones, organized industrial areas (OIZs), power plants, combined-cycle plants, and large commercial facilities such as hospitals, universities, and residential complexes. In these environments, PRMS stations ensure safe, consistent gas supply at controlled pressures suitable for various processes and devices. Even municipal gas distribution networks use scaled-down PRMS units to safely deliver gas to homes and small businesses.

In terms of sectoral applications, PRMS systems support a broad range of industries beyond energy, including glass manufacturing, cement production, ceramics, food processing, and textile operations—all of which rely heavily on natural gas for heating and production. Each industry has distinct gas usage needs in terms of flow rate, pressure range, and safety protocols, requiring tailored PRMS configurations. Adatech delivers sector-specific solutions by analyzing the unique requirements of each project and designing custom systems that optimize performance and energy efficiency. This tailored engineering approach makes PRMS systems not just a utility but a key enabler of operational success.

Automation plays a central role in enhancing the performance, safety, and efficiency of PRMS systems. Through integrated automation technologies, PRMS stations can monitor gas flow, pressure, and temperature in real time. This data is processed and visualized through SCADA (Supervisory Control and Data Acquisition) platforms, allowing operators to manage the system remotely with precision. Automated control logic enables rapid responses to changing conditions, such as pressure fluctuations or flow anomalies, without the need for manual intervention.

Remote monitoring capabilities ensure that PRMS stations are supervised 24/7. Sensors continuously collect operational data, and in the event of irregularities—like overpressure, leakage, or equipment failure—alerts are instantly transmitted to control centers. This reduces downtime, improves safety, and streamlines maintenance operations. Additionally, historical data analysis supports predictive maintenance and performance optimization. Companies like Adatech incorporate advanced automation and digitalization into every project, ensuring that each Pressure Reduction and Metering Station operates at maximum efficiency while aligning with modern smart grid practices.

Adatech produces solutions for PRMS (Pressure Reducing and Metering Station) projects with a holistic and strategic approach covering all disciplines of engineering. Compliance with international standards, engineering rigor and customer orientation are adopted as basic principles in all phases of the project from the initial idea stage to the commissioning process. The process starts with detailed feasibility analysis. The required system capacity is comprehensively evaluated technically. Then special engineering solutions are developed in line with field conditions and sectoral needs. At this point, Adatech not only installs a standard PRMS station, but also carries the system into the future by integrating project-specific automation systems, remote monitoring infrastructures and sustainability criteria.

Adatech’s sensitivity during the installation and commissioning phases is combined with a quality-oriented engineering approach. Long life, safe and efficient operation of the system is guaranteed by choosing high performance and durable equipment. Comprehensive technical documentation, user training and periodic maintenance plans are provided in every project, providing sustainable support to customers after project delivery.

Adatech’s experienced engineering staff offers customized, flexible and applicable solutions for different sectors with its experience in both local and international markets. In this respect, PRMS systems become not only an operational need but also a strategic investment that provides corporate competitive advantage. Adatech continues to be a solution partner that makes a difference in PRMS projects by combining quality, innovation and safety in engineering.

Collaborating with Adatech means not only technical success in PRMS projects, but also reliability, quality and engineering excellence. The company’s expert staff ensures maximum customer satisfaction by developing tailor-made solutions specific to each project.

Transparent communication, on-time delivery and systematic progress are prioritized at every stage of the project process. In addition, thanks to sustainability and energy efficiency-oriented designs, operating costs are reduced and environmental impact is reduced. Adatech supports the digital transformation processes of businesses by integrating PRMS systems with advanced automation and remote monitoring technologies. Offering services at international standards, the company approaches projects not only as a contractor but also as a strategic solution partner. Thanks to this visionary approach, Adatech stands out as a reliable and innovative business partner that leads the sector in PRMS projects.

In the age of digital transformation, automation has become an essential component across industries. From manufacturing to healthcare, logistics to...

Devamını Oku

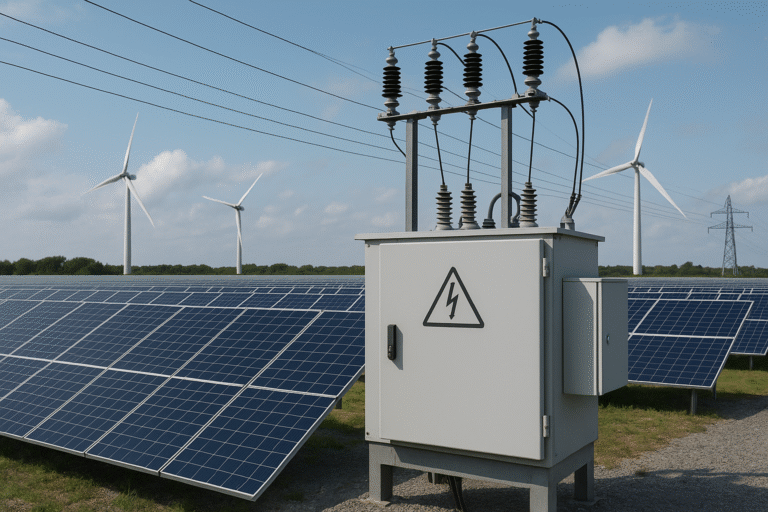

Electrification is the transition from fossil fuel-based technologies to systems that operate using electricity. It plays a pivotal role in...

Devamını Oku

Smart energy management refers to the use of advanced technologies and integrated systems to monitor, control, and optimize energy consumption...

Devamını OkuPROTECTION OF PERSONAL DATA

WEBSITE COOKIE POLICY

Your personal data; It is one of the leading principles of our Organization to protect the privacy of visitors to the website (www.adatech.com.tr) operated by ADATECH as the data controller. This Cookie Usage Policy (“Policy”) explains to all our website visitors and users which types of cookies are used and under what conditions.

Cookies are small text files stored on your device or network server by websites you visit on your computer or mobile device.

They are generally used to provide you with a personalized experience during your use of the website you visit, to improve the services offered and to improve your experience, and may contribute to ease of use while browsing a website. If you do not prefer the use of Cookies, you can delete or block Cookies in your browser settings. However, we would like to remind you that this may affect your use of our website. Unless you change your cookie settings in your browser, we will assume that you accept the use of cookies on this website.

1. WHAT KIND OF DATA IS PROCESSED IN COOKIES?

Cookies on websites, depending on their type, collect data about your browsing and usage preferences on the device you visit the site. This data includes information about the pages you access, the services and products you review, your preferred language option and other preferences.

2. WHAT is a solution and what are its intended uses?

Cookies are small text files that are stored on your device or network server through browsers by websites you visit. These small text files, which contain your preferred language and other settings on the site, help us remember your preferences the next time you visit the site and make improvements to our services to improve your experience on the site. Thus, you can have a better and personalized usage experience on your next visit.

The main purposes of using cookies on our Website are listed below:

3.TYPES OF COOKIES USED ON OUR WEBSITE

3.1. Oturum Çerezleri

Session cookies ensure that the website functions properly during your visit. They are used for purposes such as ensuring the security and continuity of our sites and you during your visit. Session cookies are temporary cookies, they are deleted when you close your browser and come to our site again, they are not permanent.

3.2. Persistent Cookies

These types of cookies are used to remember your preferences and are stored on your device via browsers. Persistent cookies remain stored even after you close your browser or restart your computer from which you visited our site. These cookies are kept in subfolders of your browser until they are deleted through your browser’s settings.

Some types of persistent cookies may be used to provide you with special suggestions, taking into account issues such as your purpose of using the Website.

Thanks to persistent cookies, if you visit our Website again with the same device, it is checked whether there is a cookie created by our Website on your device and if there is, it is understood that you have visited the site before and the content to be transmitted to you is determined accordingly and thus a better service is provided to you.

3.3. Mandatory/Technical Cookies

These cookies are essential for the website you visit to function properly. The purpose of such cookies is to provide necessary services by enabling the website to function. For example, it allows you to access secure parts of the website, to use its features, to navigate on it.

3.4. Analytical Cookies

They collect information about the way the website is used, the frequency and number of visits, and show how visitors navigate to the site. The purpose of using such cookies is to increase performance by improving the way the site functions and to determine the general trend direction. They do not contain data that could enable the identification of visitors. For example, they show the number of error messages displayed or the most visited pages.

3.5. Functional/Functional Cookies

It saves the choices made by the visitor within the site and remembers them on the next visit. The purpose of such cookies is to provide ease of use to visitors. For example, it prevents the site user from re-entering the user password on each page they visit.

3.6. Targeting/Advertising Cookies

They enable the measurement of the effectiveness of advertisements served to visitors and the calculation of the number of times the advertisements are viewed. The purpose of such cookies is to serve ads customized to the interests of visitors.

Likewise, they enable the detection of visitors’ interests specific to their browsing and the presentation of appropriate content. For example, it prevents the advertisement shown to the visitor from being shown again in a short time.

4. HOW TO MANAGE COOKIE PREFERENCES?

To change your preferences regarding the use of cookies or to block or delete cookies, simply change your browser settings.

Many browsers give you the option to accept or reject cookies, accept only certain types of cookies, or be alerted by the browser when a website requests to store cookies on your device so that you can control cookies.

It is also possible to delete cookies previously saved in your browser.

If you disable or refuse cookies, you may need to set some preferences manually, some features and services on the website may not function properly as we will not be able to recognize and associate your account. You can change the settings of your browser by clicking on the relevant link from the table below.

5. ENFORCEMENT OF WEBSITE PRIVACY POLICY

Website Privacy Policy …./…./…./…. . is dated. In case all or certain articles of the Policy are renewed, the effective date of the Policy will be updated. The Privacy Policy is published on the website of the Authority (www.adatech.com.tr) and made available to the relevant persons upon the request of the personal data owners.

ADATECH

Address: Esenyalı Neighborhood Yanyol Street Varyap Plaza No:61-148 Pendik / Istanbul

Telephone: +90 (216 ) 514 80 69

E-mail: [email protected]

Web Address: www.adatech.com.tr