Industrial automation is the backbone of modern production processes, enabling systems to operate with minimal human intervention. As industries move toward digital transformation and Industry 4.0 integration, automation technologies are key to achieving efficiency, consistency, and scalability. These systems combine machinery, software, and sensor technologies to control and monitor industrial operations. At Adatech, we deliver customized industrial automation solutions that make production lines smarter, more efficient, and sustainable.

With years of engineering experience, Adatech specializes in designing and implementing high-performance industrial automation systems across various sectors. These systems not only manage machine operations but also enable data collection, real-time monitoring, and predictive maintenance. Our portfolio of industrial automation products includes advanced controllers, sensors, and software that are tailored to meet specific operational needs. By embracing cutting-edge industrial automation technologies, we help our clients boost productivity and maintain a competitive edge in their industries.

What is Industrial Automation?

Industrial automation refers to the use of control systems such as computers, PLCs, and software to manage machinery and processes within manufacturing and production environments. These systems reduce the need for manual labor, increase production speed, and ensure consistent product quality. Automation enables continuous operation, improves accuracy, and minimizes human error, making it a vital element in today’s competitive industrial landscape.

Compared to traditional manual methods, automation provides faster decision-making, real-time monitoring, and greater control over complex operations. Industrial automation solutions include everything from basic control panels to integrated networks of smart devices. At Adatech, we use our deep engineering knowledge to implement intelligent systems tailored to each client’s operational needs. Our approach helps businesses optimize performance, lower costs, and achieve a higher return on investment.

Industrial Automation Systems

Industrial automation systems are complex infrastructures designed to control, monitor, and streamline production processes across various industries. These systems integrate hardware and software components such as PLCs, sensors, controllers, and monitoring interfaces to enable real-time decision-making and autonomous operations. By minimizing manual input and maximizing process consistency, automation systems help businesses increase efficiency, reduce downtime, and maintain high product quality.

At Adatech, we specialize in designing and implementing tailor-made industrial automation solutions for sectors such as energy, manufacturing, petrochemicals, and more. Our systems incorporate reliable industrial automation products and state-of-the-art technologies that ensure optimal performance. From planning to commissioning, we deliver fully integrated systems customized to client needs. In the sections below, we’ll explore key components of these systems, including PLC programming, SCADA, robot control, and motion systems.

PLC Programming

PLC (Programmable Logic Controller) programming is a foundational element of modern industrial automation systems. PLCs manage and execute complex control logic to operate machinery and production lines with precision and reliability. At Adatech, we develop customized PLC software that enables seamless process control, real-time communication with devices, and integration with broader automation infrastructures. Our expert engineers program PLCs to perform tasks such as timing, counting, sequencing, and conditional logic, ensuring smooth and efficient operations across various industries.

SCADA Systems

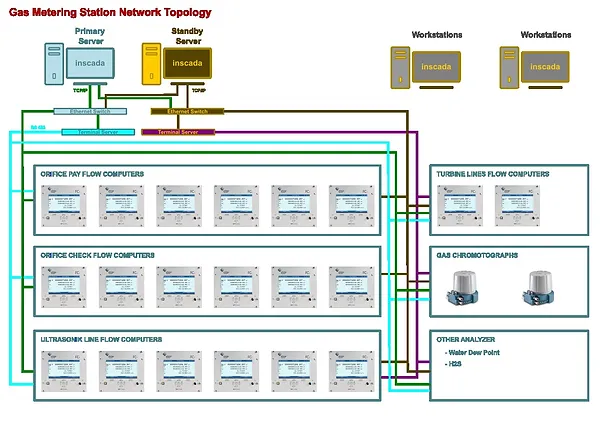

SCADA (Supervisory Control and Data Acquisition) systems are essential for remote monitoring, control, and data analysis in large-scale industrial environments. These systems provide real-time visualization of operational data, enabling faster and more informed decision-making. As part of Adatech’s advanced industrial automation technologies, our SCADA solutions offer centralized control, alarm management, and historical data tracking. This enhances operational efficiency, ensures process transparency, and reduces system downtime.

SCADA (Supervisory Control and Data Acquisition) systems are essential for remote monitoring, control, and data analysis in large-scale industrial environments. These systems provide real-time visualization of operational data, enabling faster and more informed decision-making. As part of Adatech’s advanced industrial automation technologies, our SCADA solutions offer centralized control, alarm management, and historical data tracking. This enhances operational efficiency, ensures process transparency, and reduces system downtime.

Robot Control Systems

Robot control systems are designed to manage the movements and functions of robotic arms and machines used in automated manufacturing. These systems ensure high-speed, precise, and synchronized operations for tasks such as welding, assembly, packaging, and material handling. As a provider of advanced industrial automation solutions, Adatech delivers integrated robot control systems that enhance productivity, reduce labor costs, and ensure consistent product quality across industrial applications.

Motion Control Systems

Motion control systems regulate the speed, position, and direction of machines in automated environments. Using servo motors, drives, and advanced controllers, these systems enable smooth and precise movements in high-performance production lines. Adatech integrates motion control as a critical part of its industrial automation products, delivering responsive and scalable solutions that enhance machine performance, reduce mechanical wear, and support complex motion sequences in real time.

Data Collection and Monitoring Systems

Data collection and monitoring systems play a key role in analyzing real-time operational data to ensure efficiency, quality, and preventive maintenance. These systems gather information from sensors, machines, and control units to provide insights into production performance and equipment health. As part of Adatech’s cutting-edge industrial automation technologies, our data solutions help clients track KPIs, detect anomalies early, and make data-driven decisions to optimize operations.

Industrial Automation Technologies

Industrial automation technologies encompass a wide range of advanced tools and systems that enable intelligent, efficient, and autonomous operations in industrial environments. These technologies include PLCs, SCADA, robotics, motion control systems, IoT devices, artificial intelligence, and cloud-based monitoring platforms. Each of these components plays a critical role in enhancing control, precision, and real-time decision-making across various production stages.

At Adatech, we leverage state-of-the-art industrial automation technologies to help clients digitize and future-proof their operations. Our solutions are built to adapt to evolving industry needs and provide seamless integration between hardware and software. Whether it’s optimizing production speed, reducing downtime, or ensuring product consistency, our expertise in automation empowers industries to achieve operational excellence and long-term growth.

Our Industrial Automation Application Areas

At Adatech, we deliver tailored industrial automation solutions to a wide variety of industries, helping them improve efficiency, safety, and operational accuracy. Our expertise spans across sectors such as oil and gas, energy, water treatment, food and beverage, automotive, chemicals, packaging, and manufacturing. Each project is designed to meet the unique needs of the industry, ensuring that automation is both practical and scalable.

Our fully integrated industrial automation systems handle everything from process control and data monitoring to robotics and machine synchronization. Whether it’s optimizing an assembly line or automating a power distribution network, Adatech implements solutions that reduce labor dependency, minimize errors, and increase productivity. With a focus on innovation and industry compliance, we help our clients stay competitive in a rapidly evolving technological landscape.

Why Choose Adatech?

Adatech stands out with its deep engineering expertise, commitment to innovation, and client-focused approach in delivering high-quality industrial automation solutions. From initial consultation to system design, implementation, and after-sales support, we provide end-to-end services tailored to each client’s operational requirements. Our team combines industry best practices with the latest industrial automation technologies to build scalable, reliable, and future-ready systems.

What truly sets Adatech apart is our ability to act as a strategic partner rather than just a service provider. We don’t just deliver industrial automation products; we design complete, integrated solutions that improve efficiency, safety, and cost-effectiveness. Backed by our dedication to quality and continuous improvement, we help businesses achieve their digital transformation goals while maintaining long-term operational success

The most important control systems we serve are:

PLC programming

We offer PLC solutions that enable the automatic control of industrial machines and production lines. We make your business processes more efficient, reliable, and flexible.

SCADA systems

We provide SCADA solutions that allow you to monitor, control, and report on production and facility processes in real time. We set up customized systems for efficiency and safety.

Robot control systems

We develop control solutions that enable industrial robots to operate with precision and speed. We help you achieve maximum efficiency by reducing error margins in production processes.

Motion control systems

We offer motion control systems that enable high-precision management of motors, servos, and other moving equipment. We enhance production quality with flexible and energy-efficient solutions.

Data acquisition and monitoring systems

We enable you to collect, analyze, and report all data from your production processes. We accelerate your decision-making processes with real-time monitoring.