What are Fire Alarm Systems? How Do They Work?

Fire alarm systems are essential components of modern safety infrastructure, designed to detect and alert occupants about potential fire hazards...

Devamını Oku

In industrial automation, Distributed Control Systems (DCS) play a crucial role in managing and optimizing large-scale production and process control. Unlike traditional centralized control systems, DCS distributes control functions across multiple interconnected units, enhancing system reliability, flexibility, and efficiency.

DCS is widely used in industries such as energy, petrochemicals, pharmaceuticals, and manufacturing, where complex processes require real-time monitoring and precise control. By integrating sensors, controllers, and human-machine interfaces (HMI) into a unified system, DCS ensures seamless operation and improved decision-making.

A key advantage of DCS is its fault tolerance and scalability. Since control functions are distributed, the system can continue operating even if one part fails, minimizing downtime and production losses. DCS system requirements vary based on industry needs, but typically include robust hardware, flexible software, and advanced networking capabilities.

As industries continue to evolve, DCS systems are essential for maintaining operational efficiency, reducing human intervention, and ensuring safety. Now, let’s explore what is DCS, how it works, and why it is an integral part of modern industrial processes.

DCS (Distributed Control Systems) is an advanced automation system used to manage complex industrial processes. Unlike centralized control systems, where all operations rely on a single control unit, DCS distributes control across multiple independent controllers, ensuring more efficient and fault-tolerant operations.

A DCS system consists of key components such as field devices (sensors and actuators), controllers (PLC, RTU), and human-machine interfaces (HMI). These elements work together to monitor and control processes in real time. By distributing control functions, DCS minimizes the risks of system failures, allowing industries to achieve continuous production with minimal interruptions.

One of the most important features of DCS systems is their scalability. As industrial facilities expand, additional controllers can be integrated into the system without major modifications. This flexibility makes DCS ideal for industries requiring precise and continuous process control.

Another significant advantage is real-time data acquisition and analysis. The DCS system requirements include high-speed communication networks, allowing operators to make informed decisions based on live data.

DCS systems are widely used in industries where process automation is critical, such as power plants, chemical processing, and oil refineries. These systems help businesses enhance operational efficiency, reduce downtime, and improve overall safety.

A DCS system is responsible for automating, monitoring, and optimizing industrial processes by distributing control across multiple units. This ensures that operations run smoothly, efficiently, and safely. Unlike traditional centralized systems, where a single failure can disrupt the entire process, DCS allows localized control, reducing the impact of malfunctions.

One of the primary functions of DCS systems is real-time data collection and analysis. Sensors continuously measure variables such as temperature, pressure, and flow rates, and this data is processed by distributed controllers. Operators can monitor and adjust processes through human-machine interfaces (HMI), ensuring optimal performance.

Another key feature is energy efficiency and resource optimization. DCS systems automatically adjust process parameters to minimize energy consumption, reducing operational costs while maintaining productivity. This is particularly important in energy-intensive industries like power generation, chemical processing, and oil refineries.

Additionally, DCS enhances safety by implementing automatic alarm and shutdown procedures. In case of anomalies, the system can instantly take corrective actions, preventing accidents and protecting both workers and equipment.

The scalability of DCS systems allows businesses to expand production lines without disrupting existing operations. Since DCS system requirements can be customized, industries can integrate new technologies and automation solutions seamlessly.

In summary, a DCS system ensures stable, efficient, and safe industrial operations by distributing control, enabling real-time monitoring, reducing downtime, and optimizing resources.

Using a DCS system is essential for industries that rely on automation, precision, and real-time monitoring. The ability to distribute control functions across multiple units makes DCS a reliable and efficient solution for managing complex industrial operations.

One of the primary reasons for using a DCS system is increased operational safety. Industrial processes often involve hazardous conditions, such as high temperatures, extreme pressures, and chemical reactions. DCS automatically detects irregularities and triggers alarms or shutdowns, preventing accidents and protecting both employees and equipment.

Another major benefit is improved efficiency and productivity. DCS systems continuously optimize process parameters, ensuring stable operations with minimal waste and maximum output. By reducing manual interventions, industries can increase production rates while maintaining quality standards.

DCS also enhances system reliability and fault tolerance. In a traditional centralized system, a single failure could halt production. However, DCS ensures that control functions remain operational even if one unit fails, minimizing downtime and reducing financial losses.

Additionally, DCS systems contribute to cost savings. By optimizing energy consumption and resource allocation, companies can reduce operational expenses and improve profitability. The scalable nature of DCS also allows industries to expand their operations without major infrastructure changes, making it a cost-effective long-term investment.

With advanced automation, seamless integration, and real-time monitoring, a DCS system is essential for modern industries aiming for efficiency, safety, and sustainability.

DCS systems are widely used across multiple industries that require continuous process control, automation, and real-time monitoring. These industries depend on DCS technology to ensure efficiency, safety, and reliability in their operations.

The oil and gas industry relies heavily on DCS systems for controlling refineries, pipelines, and offshore drilling operations. DCS ensures stable pressure control, temperature monitoring, and safety protocols to prevent hazardous incidents and improve operational efficiency.

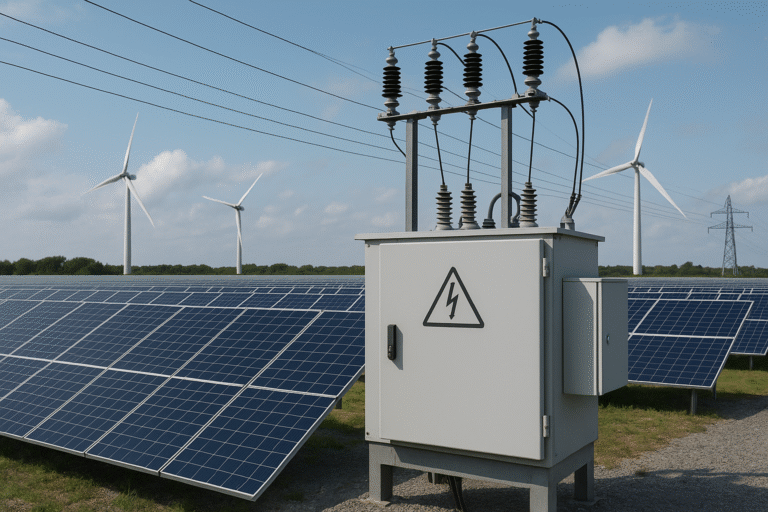

Power plants, including thermal, hydroelectric, nuclear, and renewable energy facilities, use DCS systems to manage turbines, generators, and power distribution networks. DCS optimizes energy output while minimizing fuel consumption, ensuring a more sustainable power supply.

In chemical and petrochemical plants, DCS systems regulate reaction processes, mixing operations, and material flows. By providing real-time monitoring and precise control, DCS helps prevent dangerous chemical reactions and maintains product consistency.

The pharmaceutical industry requires highly regulated and precise manufacturing processes. DCS ensures compliance with safety and quality standards by controlling batch production, ingredient measurements, and environmental conditions during drug manufacturing.

Food processing plants use DCS to control mixing, fermentation, temperature regulation, and packaging automation. The system ensures consistent product quality, reduces waste, and enhances efficiency in large-scale production.

In metal processing and mining operations, DCS systems help manage smelting, refining, and material handling. These systems enhance energy efficiency and equipment lifespan, ensuring a safe and cost-effective workflow.

Municipal water treatment facilities utilize DCS systems to monitor water purification, chemical dosing, and distribution. The system helps in maintaining water quality standards and optimizing resource usage.

Manufacturers and automotive production lines integrate DCS technology to streamline assembly lines, robotic automation, and quality inspections. DCS helps manufacturers improve efficiency, reduce downtime, and meet production targets.

By implementing DCS systems, these industries benefit from greater operational efficiency, improved safety, cost savings, and enhanced process control.

Adatech provides cutting-edge DCS solutions tailored to various industries, ensuring optimal process control, automation, and efficiency. With a focus on innovation and reliability, Adatech integrates advanced hardware, software, and network solutions to meet specific DCS system requirements.

Adatech’s DCS solutions feature real-time process automation, enabling industries to monitor and control production lines with precision. The company integrates Programmable Logic Controllers (PLC), Remote Terminal Units (RTU), and SCADA systems to optimize performance and minimize human intervention.

Adatech utilizes AI-driven analytics to enhance predictive maintenance, performance tracking, and fault detection. By leveraging real-time data collection and machine learning algorithms, businesses can reduce downtime and increase operational efficiency.

Adatech’s DCS solutions include intelligent energy management to help industries reduce energy consumption and improve sustainability. By analyzing power usage patterns and optimizing equipment performance, Adatech enables companies to lower operational costs and minimize environmental impact.

With cybersecurity threats on the rise, Adatech ensures DCS systems are protected against cyberattacks and unauthorized access. The company implements secure network protocols, encrypted communication, and firewall protection to safeguard critical infrastructure.

Adatech offers cloud-based remote monitoring and control solutions, allowing operators to access and manage DCS systems from anywhere. This feature enhances flexibility, scalability, and real-time decision-making.

Adatech understands that DCS system requirements vary across industries. The company provides customized automation solutions for oil & gas, power generation, pharmaceuticals, and manufacturing, ensuring seamless integration with existing infrastructures.

With its state-of-the-art DCS solutions, Adatech helps industries achieve higher efficiency, lower costs, and improved safety, positioning itself as a trusted leader in industrial automation.

Fire alarm systems are essential components of modern safety infrastructure, designed to detect and alert occupants about potential fire hazards...

Devamını Oku

Image processing systems are technological solutions designed to analyze, interpret, and manipulate digital images using computer-based algorithms. These systems play...

Devamını Oku

Electrification is the transition from fossil fuel-based technologies to systems that operate using electricity. It plays a pivotal role in...

Devamını OkuPROTECTION OF PERSONAL DATA

WEBSITE COOKIE POLICY

Your personal data; It is one of the leading principles of our Organization to protect the privacy of visitors to the website (www.adatech.com.tr) operated by ADATECH as the data controller. This Cookie Usage Policy (“Policy”) explains to all our website visitors and users which types of cookies are used and under what conditions.

Cookies are small text files stored on your device or network server by websites you visit on your computer or mobile device.

They are generally used to provide you with a personalized experience during your use of the website you visit, to improve the services offered and to improve your experience, and may contribute to ease of use while browsing a website. If you do not prefer the use of Cookies, you can delete or block Cookies in your browser settings. However, we would like to remind you that this may affect your use of our website. Unless you change your cookie settings in your browser, we will assume that you accept the use of cookies on this website.

1. WHAT KIND OF DATA IS PROCESSED IN COOKIES?

Cookies on websites, depending on their type, collect data about your browsing and usage preferences on the device you visit the site. This data includes information about the pages you access, the services and products you review, your preferred language option and other preferences.

2. WHAT is a solution and what are its intended uses?

Cookies are small text files that are stored on your device or network server through browsers by websites you visit. These small text files, which contain your preferred language and other settings on the site, help us remember your preferences the next time you visit the site and make improvements to our services to improve your experience on the site. Thus, you can have a better and personalized usage experience on your next visit.

The main purposes of using cookies on our Website are listed below:

3.TYPES OF COOKIES USED ON OUR WEBSITE

3.1. Oturum Çerezleri

Session cookies ensure that the website functions properly during your visit. They are used for purposes such as ensuring the security and continuity of our sites and you during your visit. Session cookies are temporary cookies, they are deleted when you close your browser and come to our site again, they are not permanent.

3.2. Persistent Cookies

These types of cookies are used to remember your preferences and are stored on your device via browsers. Persistent cookies remain stored even after you close your browser or restart your computer from which you visited our site. These cookies are kept in subfolders of your browser until they are deleted through your browser’s settings.

Some types of persistent cookies may be used to provide you with special suggestions, taking into account issues such as your purpose of using the Website.

Thanks to persistent cookies, if you visit our Website again with the same device, it is checked whether there is a cookie created by our Website on your device and if there is, it is understood that you have visited the site before and the content to be transmitted to you is determined accordingly and thus a better service is provided to you.

3.3. Mandatory/Technical Cookies

These cookies are essential for the website you visit to function properly. The purpose of such cookies is to provide necessary services by enabling the website to function. For example, it allows you to access secure parts of the website, to use its features, to navigate on it.

3.4. Analytical Cookies

They collect information about the way the website is used, the frequency and number of visits, and show how visitors navigate to the site. The purpose of using such cookies is to increase performance by improving the way the site functions and to determine the general trend direction. They do not contain data that could enable the identification of visitors. For example, they show the number of error messages displayed or the most visited pages.

3.5. Functional/Functional Cookies

It saves the choices made by the visitor within the site and remembers them on the next visit. The purpose of such cookies is to provide ease of use to visitors. For example, it prevents the site user from re-entering the user password on each page they visit.

3.6. Targeting/Advertising Cookies

They enable the measurement of the effectiveness of advertisements served to visitors and the calculation of the number of times the advertisements are viewed. The purpose of such cookies is to serve ads customized to the interests of visitors.

Likewise, they enable the detection of visitors’ interests specific to their browsing and the presentation of appropriate content. For example, it prevents the advertisement shown to the visitor from being shown again in a short time.

4. HOW TO MANAGE COOKIE PREFERENCES?

To change your preferences regarding the use of cookies or to block or delete cookies, simply change your browser settings.

Many browsers give you the option to accept or reject cookies, accept only certain types of cookies, or be alerted by the browser when a website requests to store cookies on your device so that you can control cookies.

It is also possible to delete cookies previously saved in your browser.

If you disable or refuse cookies, you may need to set some preferences manually, some features and services on the website may not function properly as we will not be able to recognize and associate your account. You can change the settings of your browser by clicking on the relevant link from the table below.

5. ENFORCEMENT OF WEBSITE PRIVACY POLICY

Website Privacy Policy …./…./…./…. . is dated. In case all or certain articles of the Policy are renewed, the effective date of the Policy will be updated. The Privacy Policy is published on the website of the Authority (www.adatech.com.tr) and made available to the relevant persons upon the request of the personal data owners.

ADATECH

Address: Esenyalı Neighborhood Yanyol Street Varyap Plaza No:61-148 Pendik / Istanbul

Telephone: +90 (216 ) 514 80 69

E-mail: [email protected]

Web Address: www.adatech.com.tr